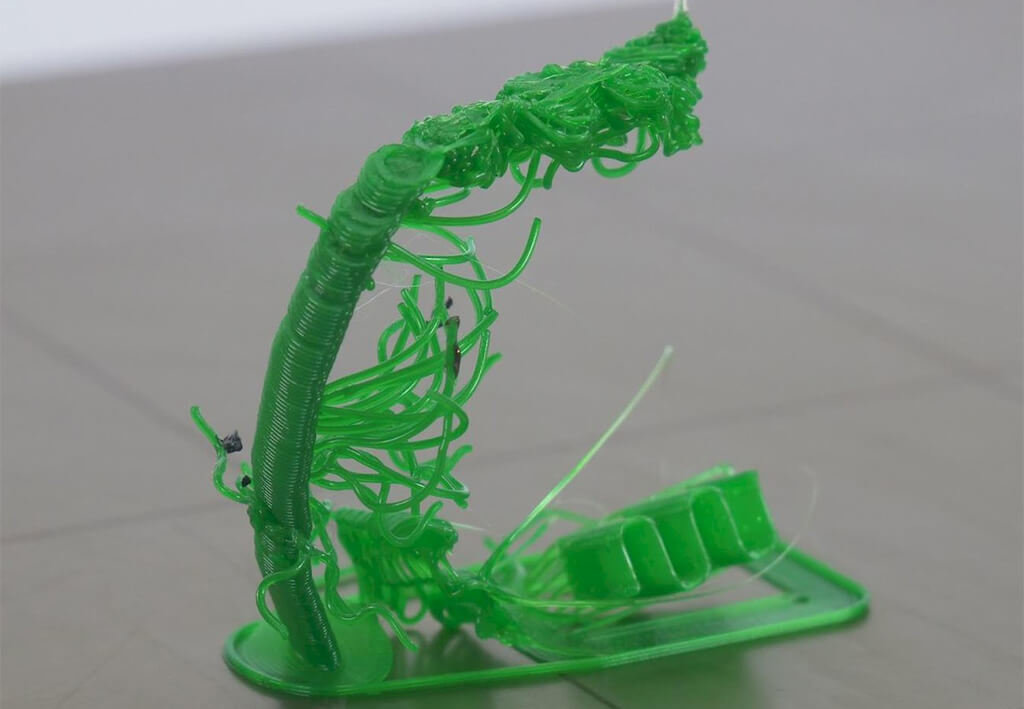

If a process requires both extruders to be hot, you can set it to dual. Simplif圓D treats a print as a series of independent "processes" each with their own set of properties and print order. If you are only using one extruder then it makes no sense for both to be at temp for hours, but if you forget to bring something back to temp later in the print you cannot extrude and end up with a mess later.

When I bought my first dual extruder printer I was having difficulty with the concept of two things working together. Simplif圓D has perfected supports and although has it right with the defaults most of the time, does have the ability to tweak things that affect the density of the material touching the part. Until this I was printing rough parts where the supports wouldn't disengage with the part itself. The supports! Supports are a dream and made printing enjoyable for me. Simplif圓D makes everything from auto-support to dual extruder configurations a breeze for. It is available at a perpetual license and support is extended via documentation, video tutorials, FAQs,

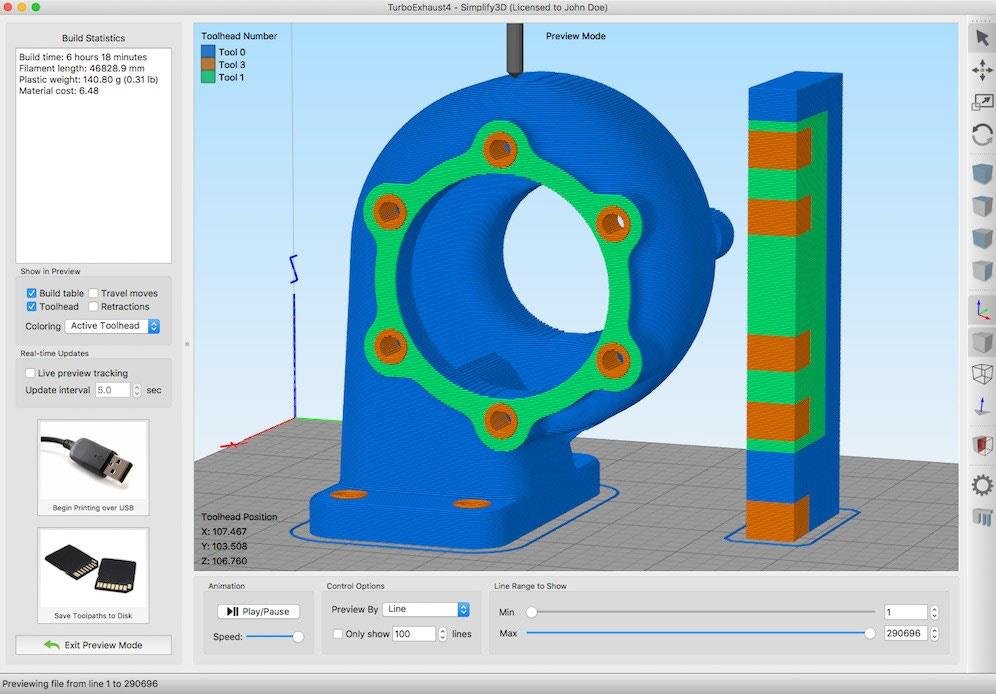

Simplif圓D allows administrators to monitor print status, insert custom commands, and manage multiple printers on a centralized platform. Additionally, it allows team members to identify and fix common mesh issues across problematic STL files. It lets supervisors optimize the print quality by handling strings, gaps, zits, and banding on a centralized platform. Simplif圓D enables employees to print small, tapering or sharp edges and utilize multi-part customization to create printing sequences for multiple objects. It allows staff members to create animations to visualize pre-print simulations, create sequences, monitor printing speeds and identify design issues, reducing overall failed prints. Simplif圓D is a 3D simulation solution that helps businesses manage 3D printing, control machines, handle mesh analysis, and more in multiple languages, including Portuguese, Spanish, English and Japanese.

0 kommentar(er)

0 kommentar(er)